What is a QMS or Quality Management System?

Heard of a Quality Management System but not sure if you’ve got one – or need one? We look at what a Quality Management System (QMS) is, what’s involved, and how it helps organisations meet the quality standards for products and services that customers expect.

Quality, in relation to products or services can essentially be defined as the degree of excellence in that product or service and how it meets a customer’s expectations. Every customer will have their own definition or perception of quality.

A QMS is the customer focused structure, processes, procedures, and resources needed by an organisation to implement, maintain and continually improve the management of quality throughout the entire organisation. QMS is a global standard that management can implement across any industry, location or business.

Implementing a QMS benefits every aspect of a company’s performance. Meeting the customer’s requirements helps to instil confidence in your organisation. This in turn increases your organisation’s competitive edge, leading to higher customer satisfaction. Ultimately, this leads to more customers, sales and repeat business. As a manager you can meet your organisation’s requirements, ensuring compliance with legal requirements, regulations and provision of products and services in the most cost and resource-efficient manner. Therefore, creating provision for expansion, growth, and profit.

These benefits offer additional advantages for company management, specifically: helping to communicate a readiness to produce consistent results; enabling a more efficient use of time and removing a need for micro-managing processes and personnel, reducing costs; ensuring that processes are accurately defined, documented and controlled; improving employee satisfaction and retention rates; and continually improving the organisation’s offerings.

What is Quality?

For a product or service, quality is the customer’s perception or definition of excellence.

Organisations, whether large or small benefit greatly by recognising a customer’s perception or definition of quality and implementing a quality system to produce a quality product or service – first time and every time.

Small businesses are always trying to minimise their costs, so often site cost is a barrier to implementing a QMS. With competition so fierce nowadays, organisations need to be able to distinguish themselves. What better way than through great customer satisfaction!! Implementing a QMS into an organisation with a quality culture can easily reduce your cost in many ways. Here a just a few:

- reducing quality issues

- addressing issues more quickly

- reducing human errors through training

- identifying new cost savings

- identifying process automation opportunities

A quality management system makes documenting data and providing accurate records easy. All of which is essential to improving the quality of products and services.

12 Steps to Implement a Quality Management System

These 12 steps are invaluable to implementing a Quality Management System. They also are applicable to any kind of business, whether small or large, or producing a product or service.

- Clarify your organisation’s vision, mission and values. Importantly, ensure all employees are educated in and understand them.

- Identify your organisation’s critical success factors (CSFs). CSFs help organisations meet objectives and achieve the company mission. CSF examples may be product quality, customer satisfaction, financial performance, or process improvement.

- Develop the metrics to measure and track the progress of your organisations CSFs. This requires goals and a way of measuring and reporting.

- Determine who your key customer groups are, that is the groups associated or within your organisation who understand what the customer requirements are, for example suppliers, employees and customers themselves.

- Ask for customer feedback as this will let you know what is important to your customer and whether you are meeting your customer’s requirements. Feedback may come from surveys, customer focus groups or social media feedback.

- Develop the survey tool appropriate for your product or service, and based on finding out what is important to your customers.

- Survey your customer groups. The feedback provides your baseline for customer perception as well as a starting point for your improvement plans as well as your progress once these improvement plans are implemented.

- Develop improvement plans based on the customer feedback. To achieve and measure your improvement plans, create them as SMART goals (specific, measurable, achievable, realistic and time-based) and assign them to specific employees for accountability.

- Resurvey your customer groups after a period of time, say 12 months, to see if and how the scores have improved. It is important to also consider changes in customer needs over that period of time.

- Monitor your critical success factors regularly. This is to not only monitor progress toward goals, but also correct any changes to organisation priorities and objectives.

- Market your satisfaction data and results, letting your potential customers know what your organisation does well, especially when it transpires into an exceptional product or service.

- Make sure that the technology used by your customers is user friendly. For example make sure your website is easy to find and both easy and intuitive to use.

What Documentation is required for a QMS?

A certified QMS requires certain types of documents. As part of the certification process, you will be guided through the documentation requirements of an ISO 9001 certified Quality Management System.

These documents are invaluable to management by:

- providing a clear overview of the company operations

- providing a better understanding of the QMS

- promoting consistency in processes

- addressing supplier management, training management, change management, risk management and compliance management

- showing the evidence of achieving goals and objectives

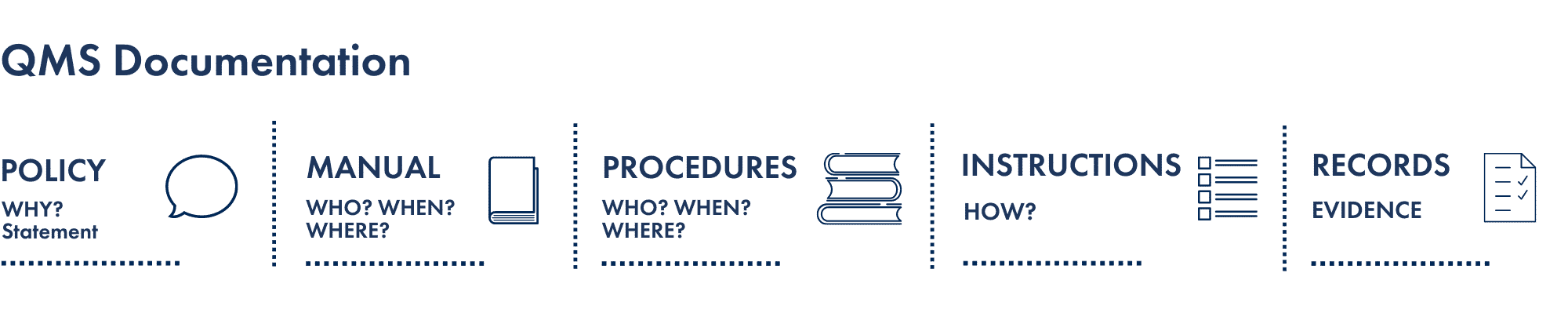

QMS documents are essentially structured in the following way:

- Quality Policy – the WHY declaration statement from the organisation, showing its commitment to quality and continual improvement

- Quality Manual – the WHO, WHEN and WHERE of your QMS scope, with the structure and content fitting your organisation depending on size and complexity of your operations and the expertise of your employees

- Quality Procedures – also the WHO, WHEN and WHERE in any format or structure, whether narrative or illustrative

- Quality Instructions – the HOW which can be part of a quality procedure or referenced in the procedure and generally in the same structure as the procedure

- Quality Records – the EVIDENCE that the processes are completed as per the Procedures and Instructions documents

Properly structured documents will make business operations much easier for both management and employees.

Is a QMS Different to Other Quality Systems?

A QMS is the customer focused process implemented by an organisation to satisfy the standards demanded by customers to satisfy their expectations. Another quality system is Total Quality Management (TQM). TQM is a complete package focusing on management’s approach to quality control, quality assurance and quality improvement success through customer satisfaction.

There are also common goals in quality systems like TQM and QMS, for example running a failure modes and effects analysis (FMEA) to identify and analyse potential risks and problems according to severity and likelihood, then determining the root causes and implement appropriate corrective action to eliminate the risk or problem.

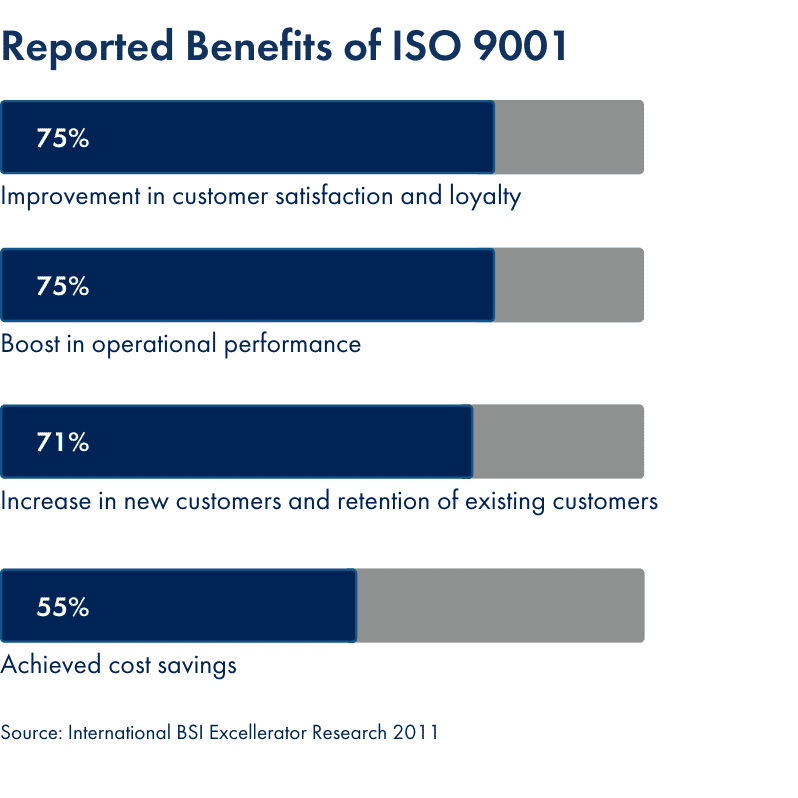

What Benefits will a Quality Management System Bring to your Business?

Implementing a quality management system will result in many long-term gains for your business, your customers and your employees. Here are just some of the benefits of effectively implementing a QMS:

- Achieve your organisational goals

- Reduce costly errors and wastage in your business

- Boost your customer satisfaction

- Market your business more effectively

- Manage growth more effectively

- Improve documentation availability

- Taking corrective action of any issues for continuous improvement of products and services

- Grow your market share in new territories and/or market sectors

- Create a culture of quality in all levels of your organisation

- Embed vision into all projects

- Improve internal communications

- Create consistency in your products and services

- Effectively measure performance of your employees and teams

- Improve compliance and compliance management

In business, we all know that time is money. Any time you invest in implementing quality control processes and policies up front, will save time in the long run. Employees will learn and know what do, how to do it and when to do it. With a Quality Management System in place and the effective use of risk management and change management, the system will ensure that mistakes are few and far between. This will save you time and money, improve customer satisfaction and make your workplace a happier environment for your employees.

If you are considering integrating quality and structure into your business with a QMS implementation and certification we recommend you find a provider who sees Quality Management System certification as more than just a tick in a box. Look for a provider who will add the human touch and take the time to not only understand your business but to partner with and support you through the certification process and beyond for your organisation’s ongoing success in continuous quality improvement.

At Southpac Certifications, we believe in doing things differently.

We know businesses are tired of the same old tick and flick approach, which is why we have built our reputation around Certification Differently – taking a fresh approach to certification.

We want the organisations we work with – both big and small – to see the benefits and success that ISO Certification can facilitate. We truly believe that effective management systems are a key enabler of that success and working with the right certification body can drive material improvements in system performance, resilience and reliability.